Product Categories

Gongyi Lantian Machanical Plant > Industry News > Views

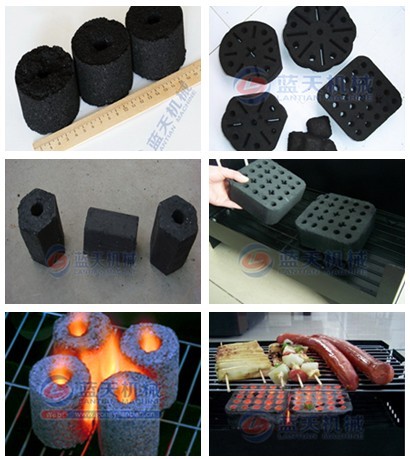

About how the clean BBQ Charcoal Making Machine carbonized we make a simple introduction to the customer's .

There are a lot of raw materials for BBQ Charcoal Making Machine, municipal solid waste, palm shell, coconut shell, biomass waste such as peanut shell, rice husk, wood, straw, sawdust, etc.

In order to achieve the desired carbonization effect, the moisture content of raw materials should be less than 20% and the feed size shall not be greater than 30mm. Therefore, the BBQ Charcoal Making Machine

should be set differently for different feeds.

After the raw materials are pre-processed by the barbecue charcoal machine, the raw materials need to be transported to the carbonization furnace and heated for 30 minutes using traditional fuels such as wood, coal and natural gas. Flammable gases and charcoal can be produced in the furnace when temperatures reach certain values. The process lasts between 15 and 20 minutes, and the temperature in the furnace is about 650℃ to 780℃.

As we all know direct emissions hot charcoal is relatively dangerous, because hot charcoal can direct contact with oxygen cause big accidents, so our system of charcoal machine is equipped with the cooling system can directly reduce the 30 ℃, then directly collected. The whole process of our BBQ Charcoal Making Machine is in a completely closed state. It is necessary to ensure a safe working environment for the barbecue charcoal production plant.

The company's barbecue carbon production machine adopts the combustible gas purification process of spay dust removal system to remove the sulfur composition and then recycle the material heating furnace and dryer, which is called "one step or two fire". This not only saves energy, but also reduces air pollution. Energy-saving and environment-friendly charcoal molding machine is the good equipment to meet the market.

In addition, the combustible gas produced in the whole production process will be liquefied by the condenser system to produce tar and wood vinegar respectively. These materials are of high temperature resistance, durability and corrosion resistance.